Injection Mold Making & Tooling Services

RpMolds delivers comprehensive injection mold making services with precision engineering, advanced CNC technology, and expert craftsmanship. Our custom injection mold manufacturing solutions serve automotive, medical, electronics, and consumer industries worldwide with exceptional quality and reliability.

20+

Years Experience

Custom Injection Mold Manufacturing Solutions

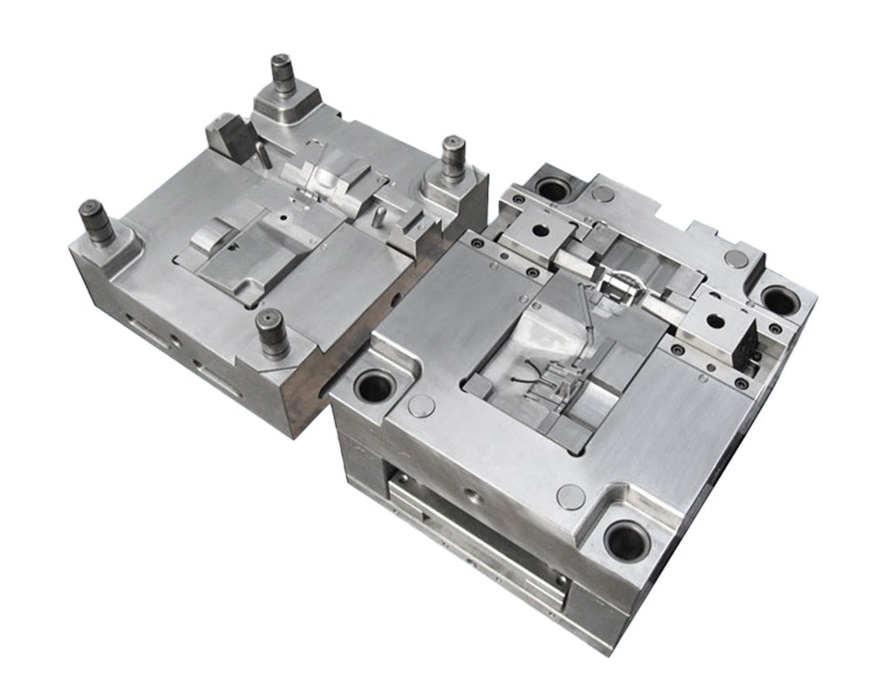

Single Cavity Molds

Cost-effective injection mold making services for prototyping and low to medium volume production.

- Lower tooling cost

- Easier maintenance

- Ideal for prototyping

- Quick modifications

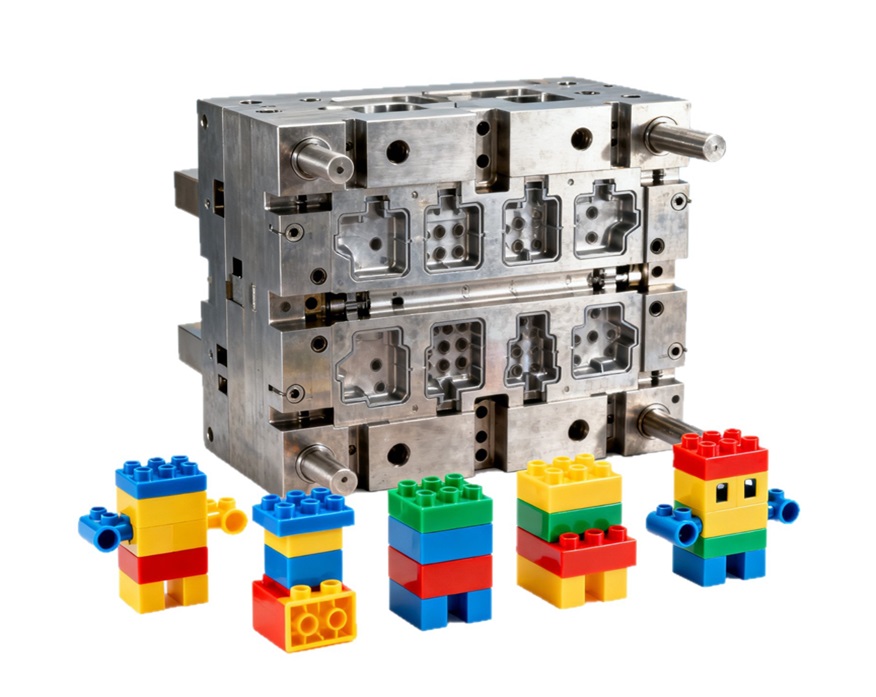

Multi-Cavity Molds

High-output injection mold manufacturing for large volume production with consistent part quality.

- Higher productivity

- Lower unit cost

- Balanced runner systems

- Up to 128 cavities

Family Molds

Multiple different parts in one mold for assembly components, reducing tooling investment.

- Multiple parts per shot

- Assembly components

- Reduced tooling cost

- Synchronized production

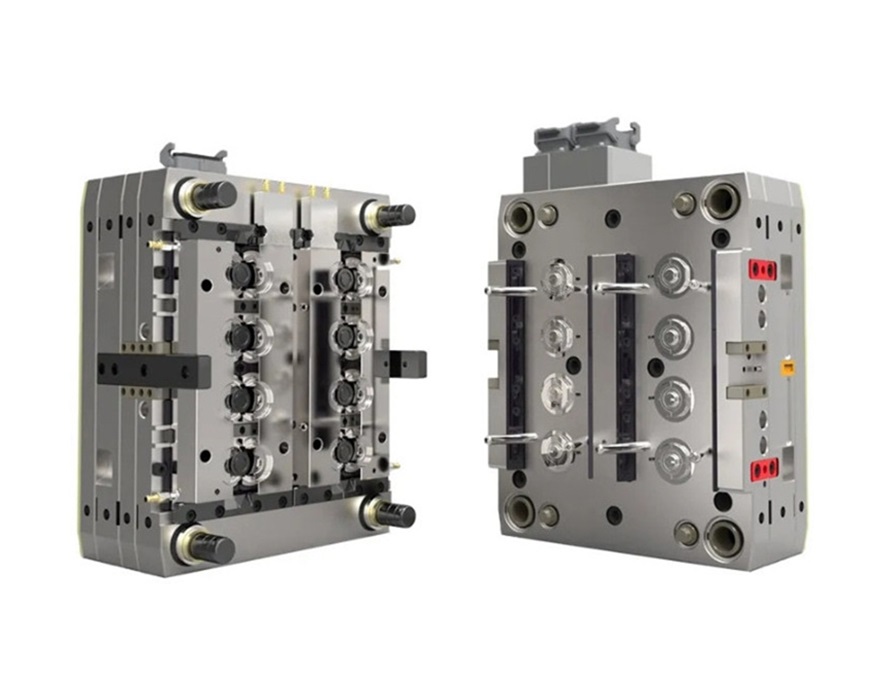

Stack Molds

Double or triple the output without increasing machine size or clamp tonnage requirements.

- 2-4x output

- Same machine

- Space efficient

- Lower costs

Advanced manifold systems for material savings, faster cycles, and improved part quality.

- No runner waste

- Faster cycle times

- Improved part quality

- Automated operation

Specialized tooling for over-molding and insert molding applications with precise positioning.

- Metal-plastic bonding

- Precise insert location

- Multi-material parts

- Complex assemblies

Injection Mold Manufacturing Capabilities

and skilled technicians to deliver molds of exceptional quality.

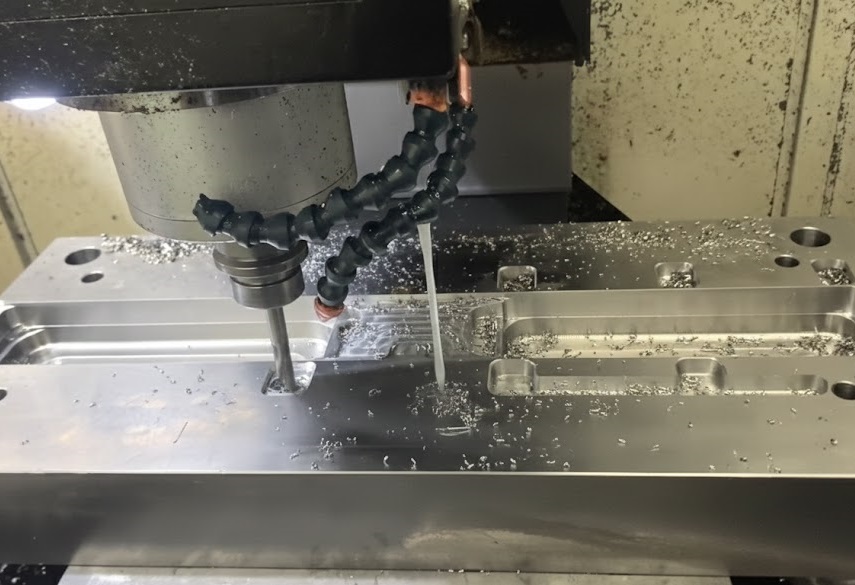

Precision CNC Machining

State-of-the-art 3, 4, and 5-axis CNC machining centers deliver injection mold making services with tolerances up to ±0.005mm for complex geometries.

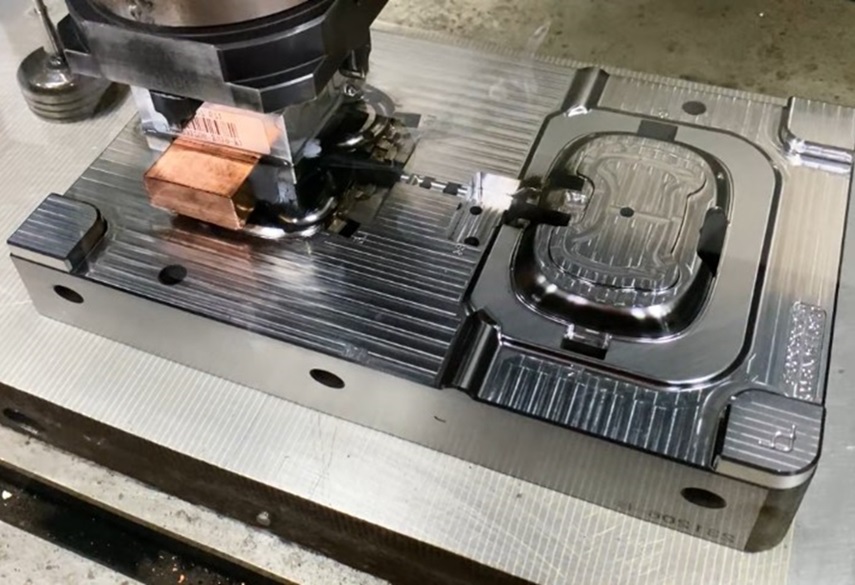

EDM Processing

Wire EDM and sinker EDM capabilities for intricate mold details, enabling custom injection mold manufacturing with sharp corners and complex cavities.

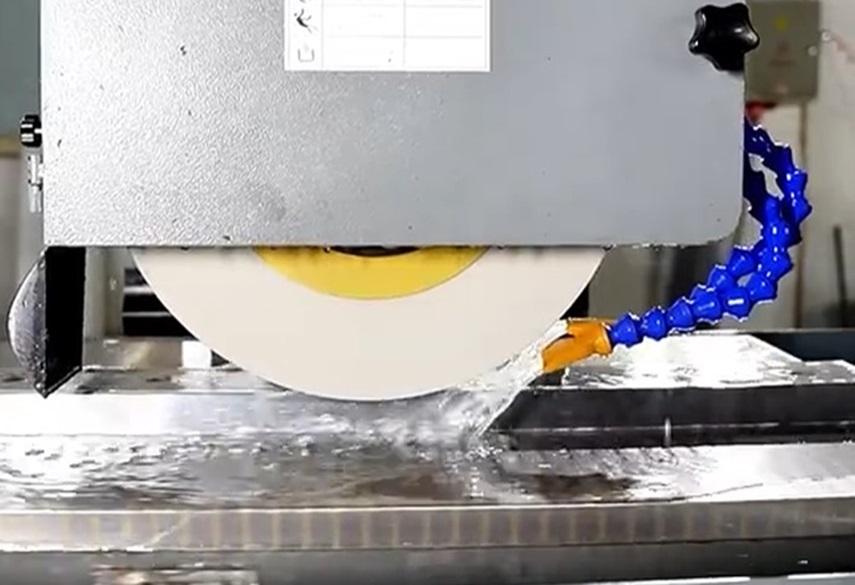

Precision Grinding

High-accuracy surface and cylindrical grinding ensures critical mold components meet exact specifications for injection mold manufacturing.

Surface Treatment

Full range of surface treatments including mirror polishing, texturing (VDI/Mold-Tech), and coating as part of our injection mold tooling services.

Deep Hole Drilling

Gun drilling technology for precise cooling channel placement, optimizing cycle times in our injection mold making services.

CMM Inspection

Advanced coordinate measuring machines provide 100% inspection for custom injection mold manufacturing quality assurance.

Injection Mold Tooling Process

Comprehensive Design for Manufacturability review to optimize part design and mold construction.

3D mold design using advanced CAD/CAM software with mold flow analysis and cooling optimization.

Selection and procurement of premium mold steels from certified suppliers worldwide.

Multi-axis CNC machining, EDM, and grinding for all mold components to exact specifications.

Expert assembly by skilled toolmakers with precise fitting and alignment of all components.

Comprehensive mold testing, sampling, and parameter optimization until approval.

Premium Mold Steels

We use only certified premium tool steels to make molds and ensure optimal mold performance, durability, and part quality. Steel selection is customized based on your production requirements.

100%

Certified Steel

6+

Steel Grades

1M+

Shot Life

| Steel Grade | Hardness | Application |

|---|---|---|

| P20 | 28-32 HRC | General purpose, medium volume production |

| 718H | 36-40 HRC | High volume, improved wear resistance |

| H13 | 48-52 HRC | High temperature, die casting applications |

| S136 | 48-52 HRC | Corrosive materials, optical parts |

| NAK80 | 38-42 HRC | Mirror polish, high-gloss requirements |

| Stavax | 48-52 HRC | Medical, food-grade applications |

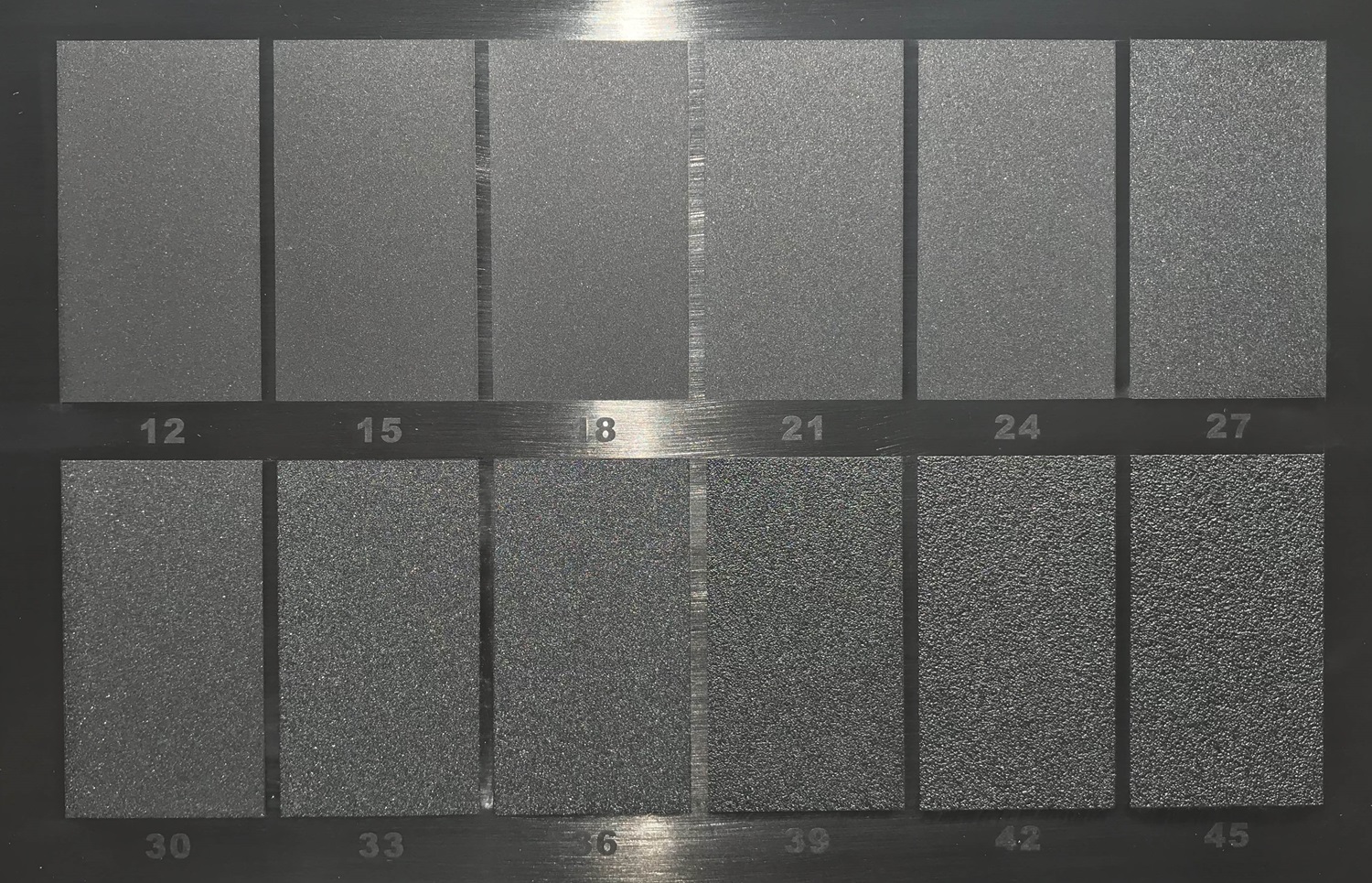

Injection Mold Surface Finishes

We offer comprehensive surface finishing options following VDI 3400 standards and SPI standards to meet your exact aesthetic and functional requirements.

| Grade | Ra Value | Type |

|---|---|---|

| VDI 12-15 | 0.40 - 0.56 μm | Light polish/fine matte |

| VDI 18-21 | 0.80 - 1.12 μm | Light texture/sandblast |

| VDI 24-27 | 1.60 - 2.24 μm | Medium sandblast/EDM |

| VDI 30-33 | 3.15 - 4.50 μm | Medium/Standard EDM |

| VDI 36-45 | 6.30 - 18.0 μm | Coarse to extreme EDM |

Need Custom Texturing?

We also offer Mold-Tech patterns and custom textures. Our team can help select the optimal finish for your application.

Why Choose RpMolds

We combine advanced mold manufacturing technology with decades of expertise to deliver injection molds that exceed expectations.

Expert Engineering Team

Skilled mold designers and toolmakers with Two decades experience

Advanced Equipment

Latest CNC, EDM, and grinding technology for precision components

Fast Turnaround

3-8 weeks lead time depending on complexity

Quality Guarantee

100% inspection with comprehensive quality reports

Industries Served

Our custom mold manufacturing expertise spans multiple industries, delivering molds for demanding applications.

Automotive

injection mold for interior, exterior, and under-hood components.

- Dashboard parts

- Trim components

- Lighting housings

- Structural parts

Medical Devices

Custom mold meeting ISO 13485 standards for healthcare applications.

- Diagnostic housings

- Surgical tools

- Drug delivery devices

- Lab consumables

Consumer Electronics

mold tooling for electronic device components.

- Device enclosures

- Button assemblies

- Connectors

- Internal structures

Home Appliances

Durable mold for household product components.

- Control panels

- Housing parts

- Handles & knobs

- Internal mechanisms

Start Injection Mold Making Today

Contact our manufacturing experts to discuss your requirements and receive a competitive quote for our injection mold tooling services.

FAQs

Find answers to common questions about our injection mold making and injection mold tooling services.

What are injection mold making services?

Injection mold making services encompass the complete design, engineering, and manufacturing of precision molds used in plastic injection molding. Our services include DFM analysis, 3D mold design, CNC machining, EDM processing, assembly, and trial runs to ensure your mold produces high-quality parts consistently.

How long does injection mold manufacturing typically take?

Injection mold manufacturing lead times range from 3 to 8 weeks depending on mold complexity, size, and specifications. Simple single-cavity molds can be completed in 3-4 weeks, while complex multi-cavity or hot runner molds may require 6-8 weeks. We offer expedited injection mold tooling services for urgent projects.

What is the cost of custom injection mold manufacturing?

Custom injection mold manufacturing costs vary based on mold size, complexity, number of cavities, steel grade, and surface finish requirements. Simple prototype molds may start from a few thousand dollars, while production-grade multi-cavity molds can range from $10,000 to $100,000+. Contact us for a detailed quote based on your specific requirements.

What industries do your injection mold tooling services support?

Our injection mold tooling services support a wide range of industries including automotive, medical devices, consumer electronics, home appliances, packaging, and industrial components. We have extensive experience meeting industry-specific standards such as ISO 13485 for medical and IATF 16949 for automotive applications.

What types of molds can you manufacture?

Our injection mold making services cover all mold types including single-cavity molds, multi-cavity molds (up to 128 cavities), family molds, hot runner molds, stack molds, insert molds, overmolds, and two-shot molds. We select the optimal mold configuration based on your production volume and part requirements.