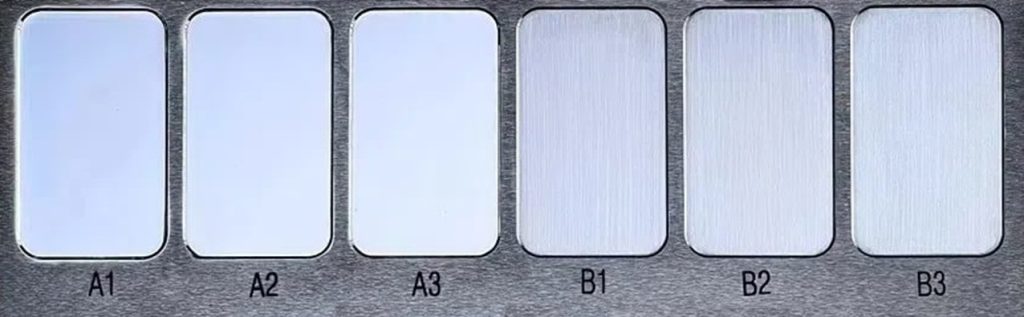

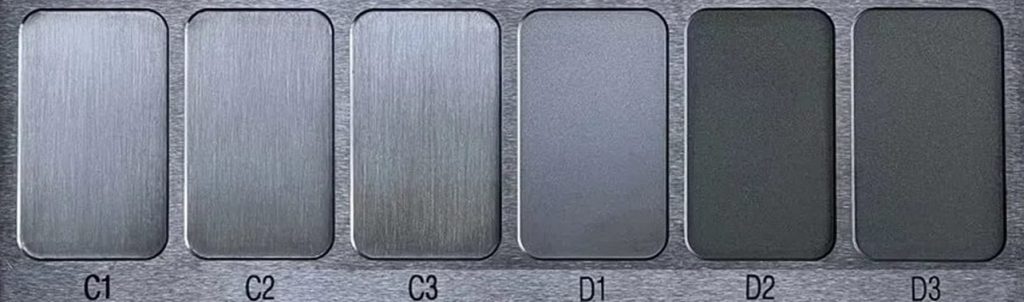

SPI Surface Finish Standards

We follow the Society of the Plastics Industry (SPI) finish standards to deliver precise surface qualities. From mirror-polish A-grades to textured D-grades, we match the exact finish your application requires.

SPI Finish Categories

Highest gloss finish achieved with diamond compound polishing. Ideal for optical parts, lenses, and transparent components requiring crystal clarity.

Semi-gloss to matte finish using grit paper. Suitable for cosmetic parts where high-gloss is not required but good appearance is essential.

Matte finish using stone polishing. Ideal for industrial parts where appearance is secondary to function but still requires a clean finish.

Textured surface created by dry blasting. Perfect for grip surfaces, hiding flow marks, or creating specific tactile properties.

| Grade | Ra Value | Method |

|---|---|---|

| A-1 | 0.012 – 0.025 μm | Grade #3 Diamond Buff |

| A-2 | 0.025 – 0.05 μm | Grade #6 Diamond Buff |

| A-3 | 0.05 – 0.10 μm | Grade #15 Diamond Buff |

| B-1 | 0.05 – 0.10 μm | 600 Grit Paper |

| B-2 | 0.10 – 0.15 μm | 400 Grit Paper |

| B-3 | 0.28 – 0.32 μm | 320 Grit Paper |

| C-1 | 0.35 – 0.40 μm | 600 Grit Stone |

| C-2 | 0.45 – 0.55 μm | 400 Grit Stone |

| C-3 | 0.63 – 0.70 μm | 320 Grit Stone |

| D-1 | 0.80 – 1.00 μm | Dry Blast Glass Bead |

| D-2 | 1.00 – 2.80 μm | Dry Blast Oxide |

| D-3 | 3.20 – 18.0 μm | Dry Blast |