Plastic Injection Molding Services

From prototype to mass production, we provide comprehensive plastic injection molding services with state-of-the-art machinery, scientific molding processes, and rigorous quality control. Our facility operates 24/7 to meet your production demands with consistency and precision.

Industries We Serve

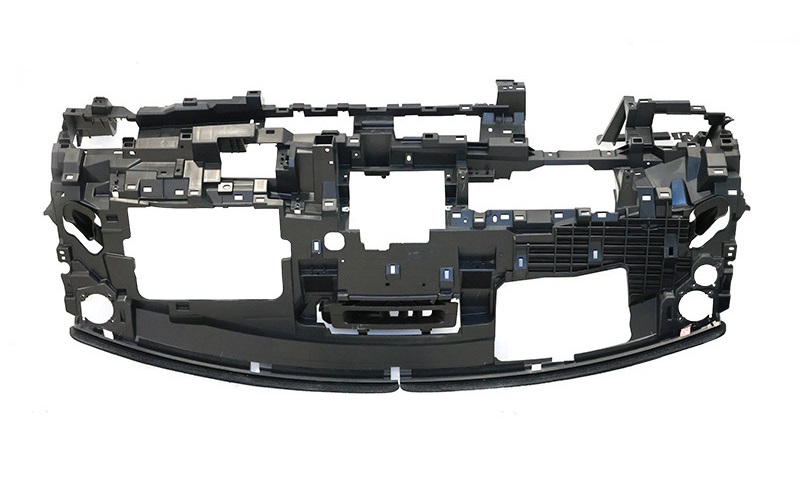

- Interior trim

- Dashboard components

- Lighting housings

- Under-hood parts

- Device housings

- Connectors

- Buttons & keypads

- Internal structures

- Diagnostic housings

- Drug delivery

- Surgical instruments

- Lab consumables

- Control panels

- Handles & knobs

- Internal components

- Housing parts

Our Machine Fleet

Our injection molding facility features over 60 machines. All machines are equipped with robotic automation and real-time monitoring systems.

| Tonnage | Quantity | Application |

|---|---|---|

| 50-100T | 12 Units | Small precision parts, electronics, medical |

| 120-200T | 18 Units | Medium parts, automotive components, consumer goods |

| 250-450T | 15 Units | Large components, housings, structural parts |

| 500-850T | 8 Units | Large housings, automotive panels, industrial parts |

| 1000-1500T | 4 Units | Extra-large parts, bumpers, containers |

| 2K Machines | 6 Units | Multi-material, multi-color applications |

Injection Molding Materials

Production Process

Material drying, color mixing, and quality verification to ensure optimal processing conditions.

Precision mold installation, cooling line connection, and parameter optimization for each run.

Scientific molding approach with DOE to establish optimal process parameters and windows.

Automated production with real-time monitoring, statistical process control, and quality checks.

In-process inspection with CMM, vision systems, and comprehensive dimensional verification.

Secondary operations including assembly, pad printing, ultrasonic welding, and packaging.

Ready to Start Production?

From low-volume prototyping to high-volume mass production, we have the capacity and expertise to bring your plastic parts to life.

FAQs

Find answers to common questions about our plastic injection molding services and capabilities.

What is plastic injection molding and how does it work?

What are the minimum and maximum part sizes you can produce?

What materials can you process for injection molding?

What is the typical lead time for injection molded parts?

Lead times depend on the complexity of your project. For existing molds, production samples can be ready in 1-2 weeks. For new molds, tooling typically takes 3-6 weeks depending on complexity, followed by sampling and production. We offer expedited services for urgent projects and maintain 24/7 production capability for high-volume orders.

What tolerances can you achieve with injection molding?

What is 2K or multi-shot injection molding?

Do you offer secondary operations for molded parts?

What quality certifications do you hold?

We are certified to ISO 9001:2015 for quality management, IATF 16949 for automotive quality standards, and ISO 13485 for medical device manufacturing. Our facility employs comprehensive quality systems including incoming inspection, in-process monitoring, SPC, and final inspection with CMM and optical measurement systems.

What is the minimum order quantity for injection molding?

Our minimum order quantities are flexible based on your needs. We support low-volume production runs starting from a few hundred pieces for prototyping and pilot production, up to millions of parts for mass production. We’ll work with you to find the most cost-effective approach for your specific volume requirements.

How do you ensure consistent part quality in high-volume production?

We use scientific molding methodology, real-time process monitoring, and statistical process control (SPC) to maintain consistency. All machines are equipped with sensors monitoring key parameters. We conduct regular inspections, maintain detailed production records, and perform capability studies to ensure every part meets specifications throughout the production run.